A novel approach for the assembly of 3D structures on a microscale guided by mechanical buckling was developed by the Center for Mechanics and Materials, School of Aerospace Engineering

In 2015, Yihui Zhang, an Associate professor from School of Aerospace Engineering at Tsinghua University, published a paper in Science (as a correspondence author) and another one in Proceedings of the National Academy of Sciences of the United States of America (as the first author), reporting a novel assembly approach for constructing three-dimensional (3D) micro/nanostructures with various high-performance materials. This provides a new route to fabrication of advanced micro/nano-systems. Prof. Yihui Zhang obtained his Ph.D. at Tsinghua University in 2011, and started working at Tsinghua University in 2015, after being awarded the Thousand Young Talents Program of China.

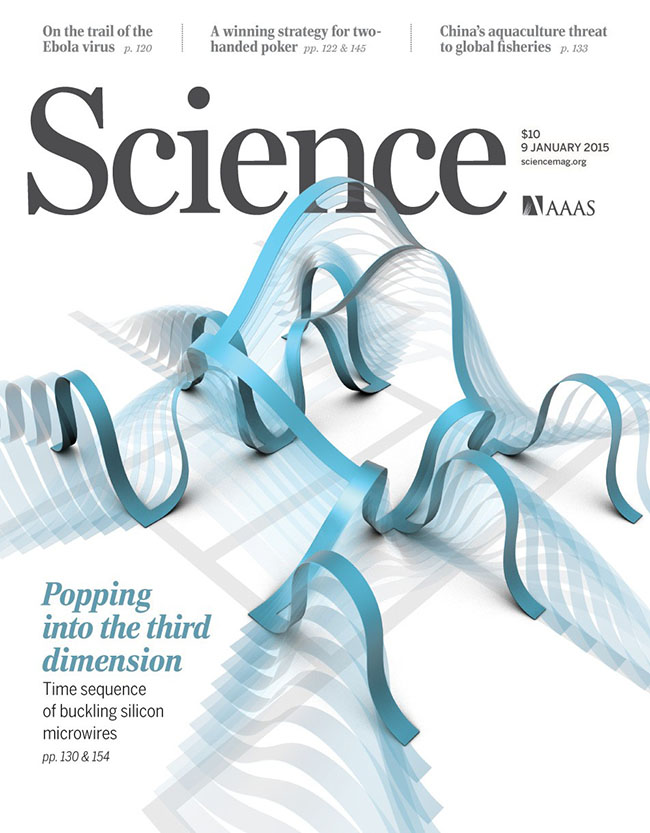

The above paper published in Science was selected as a cover feature article of Science. After the publication of this work, it was soon reported and/or highlighted, in the sections of “Perspectives” or “Research Highlights”, by Science, Nature and other journals. This work was also tracked by several professional organizations (e.g., Chemistry Views, IOP Physics World, Nano Today, and etc.), and reported by many medias (e.g., BBC, Discovery News, and etc.).

Dynamic transformation of a two-dimensional microscopic silicon ribbon into a three-dimensional structure

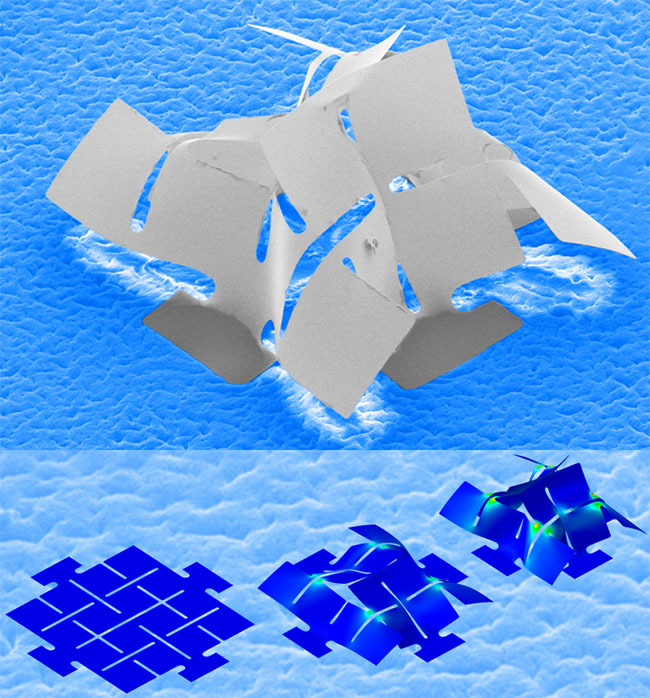

3D micro/nanostructures have important and widespread applications across a broad range of technological fields, such as biomedical devices, MEMS, optoelectronics, metamaterials, and thereby, have been viewed as the key focus of many research areas for a long time. The previous assembly/fabrication approaches of 3D micro/nanostructures have certain limitations, mainly in the applicable classes of materials and 3D geometric configurations. Especially, the existing approaches cannot be used to form complex 3D structures of high performance semiconductor materials (such as single-crystal silicon).

The assembly approach developed by Prof. Yihui Zhang and his collaborators introduces, for the first time, the controlled mechanical buckling into the assembly of 3D structures at microscale, achieving a high precision assembly of 3D meso/microstructures from 2D micro/nano-films. This method apply not only to a broad set of materials (e.g., semiconductor, polymer, metal and plastic), but also to a wide range of length scales, for example, from 100 nm to 30 mm. Compared with the technique of 3D printing, the current approach has many advantages, e.g., with a wide range of applicable materials, a fast speed of assembly, and a high degree of controllability in the assembly. Professor V.V. Tsukruk from Georgia Institute of Technology made a comment on this work, at the Perspectives Section published in the same issue of Science: the authors “demonstrate a new paradigm of designing functional materials that can quickly snap into complex 3D architectures via localized buckling.”

Results of theoretical prediction and experiment on the assembly process of a silicon structure with three-dimensional surface configurations

The above series of papers result from deep research collaborations among the groups of Prof. Yihui Zhang at Tsinghua University, Prof. Yonggang Huang at Northwestern University, and Prof. John A. Rogers at UIUC. The work published in Science was recently selected as one of the 20 candidates in the selection of “The top ten news regarding the progresses of world's science and technology in 2015”, which is sponsored by Chinese Academy of Sciences and Chinese Academy of Engineering. The above work is one of the few candidates in which there are Chinese institutions participated.